| Sign In | Join Free | My xuijs.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xuijs.com |

|

Brand Name : EPIC Powder

Model Number : SRM 800, SRM 900, SRM 1000

Certification : ISO, CE

Place of Origin : Qingdao City, Shandong Province,China

MOQ : Negotiated

Price : Negotiable

Payment Terms : L/C, D/P, T/T, Western Union, MoneyGram

Supply Ability : Negotiated

Delivery Time : 60 - 90 days after down payment received

Packaging Details : Steel Pallet & Wooden Case

After-sales Service Provided : Engineers available to service machinery overseas

Name : Industry Superfine Pulverizer Kaolin Calcium Carbonate Grinding Roller Mill

Product fineness : d97: 5 - 75 micron

After-sale service term : Lifetime service

Automation : PLC, HMI, Remote Computer Control

Process engineering service : Available

Civil engineering service : Available

Drawing software : 3D by Solidworks/ProE/Ug, 2D by AutoCAD

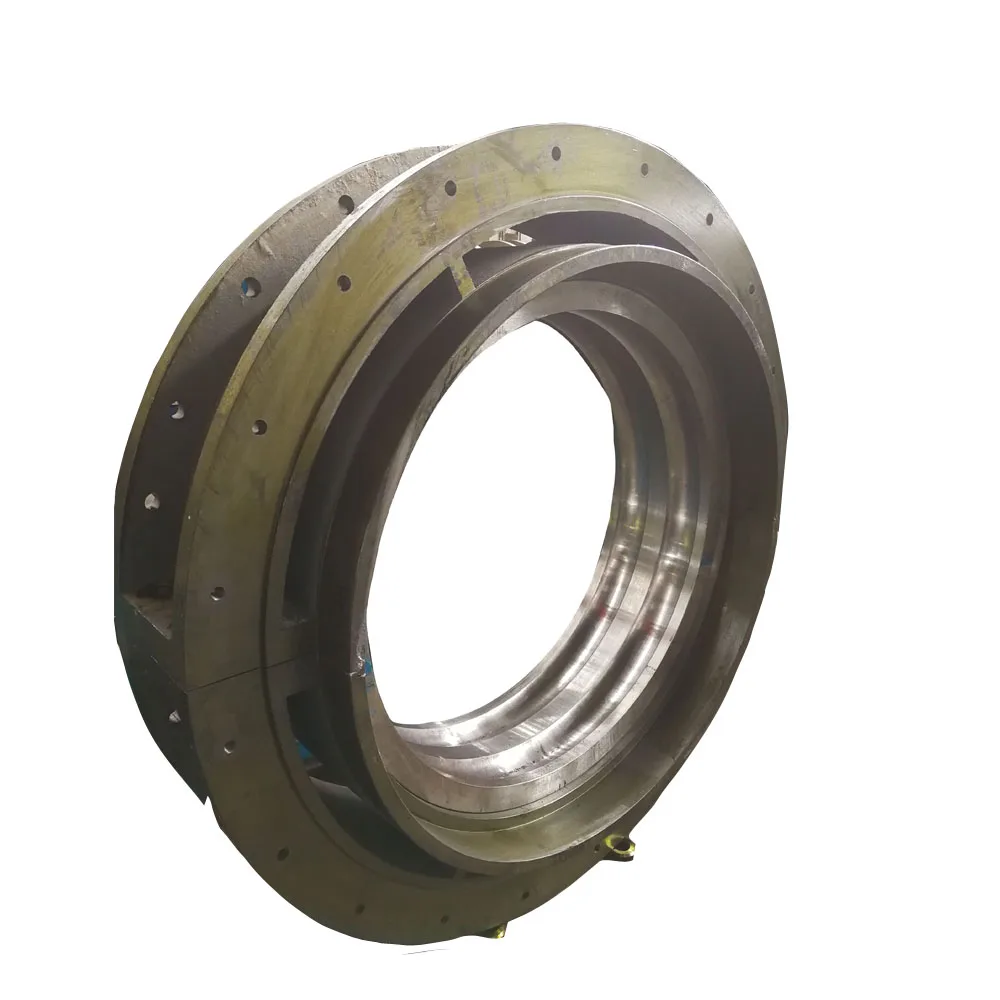

Superfine Roller Mill 5-10 um Particle Size

With Large Capacity

Superfine roller mill is proven to be the most efficient dry grinding machine, if compared with traditional grinding

machines like ball mill, impact mill, jet mill. It was designed to achieve lower energy consumption than ball mill for

non-metallic mineral powder grinding in the beginning, and now it has expanded its application to other industries

like fine chemicals, construction material, high-tech new material.

Pictures & detail

| Model | Feed Size(mm) | Moisture(%) | Fineness(um) | Capacity(t/h) | Mill Motor(Kw) |

| SRM-800 | <10 | <5 | 5-75 | 0.7-6 | 75 |

| SRM-900 | <10-15 | <5 | 5-75 | 1.4-12 | 110 |

| SRM-1000 | <10-20 | <5 | 5-75 | 2.1-18 | 132-160 |

FAQ

1) What are our main products?

- We design and manufacture various powder grinding mills, classifiers, coating machines, mixing machines, etc.

2) What service do we supply?

- We offer consultancy for project feasibility assessment, process flow definition, preliminary layout and factory building

plan, project budget, project time schedule, etc.

- We supply sample processing tests in our test station where are equipped with our various machine products, to help

clients compare performances of different types of machines or process.

- We supply project engineering, automation engineering and civil engineering.

- We send engineers to the clients’ project site and offer on-site technical instruction and supervision during the machine

installation, commissioning and test run.

3) How long time is our delivery?

- 60 to 90 days after the down payment received.

4) What payment terms do we offer?

- 30% by T/T as down payment;

- 70% by T/T before shipment or irrevocable L/C at sight.

5) What kind of shipment can we do?

- For complete machines, standard containers or frame containers by sea.

- For spare parts, wooden Case and pallet for delivery by air.

6) What service can we supply for machine installation and test run?

- We send engineers to the clients’ project site and offer on-site technical instruction and supervision during the machine

installation, commissioning and test run.

7) What is our warranty policy?

- We offer warranty of 12 months after installation or 18 months after the delivery.

- We offer lifetime service for our machine products after the delivery, and will follow up the machine status with our clients

after the successful machine installation in our clients’ factories.

For details, please check our website: www.epicmilling.com

|

|

Remote Computer Control Fine Grinding Mill Process Engineering Service Images |